3D Printing Alloy Spherical Niobium Powder

The price of nickel and stainless steel rose together. Nickel afternoon hand in hand with stainless steel together turn red up. Due to the temporary easing of geopolitical risks, risk assets are now picking up, nonferrous metals, stock markets, and so on have risen, the overall mood has temporarily improved. Ore prices are strong, the overlay of the epidemic on spot logistics or the formation of a certain impact. Phase, nickel and stainless steel materials to maintain high wide concussion pattern.

Nickel prices based on low inventory, tight supply and demand will still show high wide fluctuations. In addition, the current LME has low liquidity, so its sensitivity to capital will remain relatively high. Shanghai nickel-wide fluctuations are expected to continue in the 200,000-250,000 yuan wide repeated fluctuation trend. While stainless steel is affected by the stronger nickel pig iron, the cost support continues, but note that under the current demand is not effectively released, the upward space may also be affected, the stage is expected to fluctuate between 20000 and 22,000 yuan. The price of nickel produced such fluctuations, indicating that the price of the Spherical Niobium Powder may also be affected to a certain extent.

About 3D Printing Alloy Spherical Niobium Powder:

Product name: Spherical Niobium Powder

Product Specifications: 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm. (Can be customized according to customer requirements)

Powder properties: high purity (≥99.9%), low oxygen (≤600ppm), high sphericity (≥98%), smooth surface, no satellite ball, uniform particle size distribution, excellent flow performance (≤15.0s/50g), high loose density (≥4.5g/cm3) and vibration density (≥5.5g/cm3).

Applicable technology: Laser/electron beam additive manufacturing (SLM/EBM), laser direct deposition (DLD), hot isostatic powder molding (HIP), metal injection molding (MIM), powder metallurgy (PM), laser deposition (LC) and other processes.

Powder application: Niobium is the lightest refractory metal, with high melting point, high high temperature strength and specific strength, no radioactivity and other characteristics, is the preferred thermal protection materials and structural materials for aerospace engines. Radio frequency plasma spheroidized niobium powder has the characteristics of high sphericity, good fluidity, high purity, large loose density, full density inside the particle, no hollow powder and so on. It is widely used in vacuum coating, hot spray coating, cold spraying and other fields.

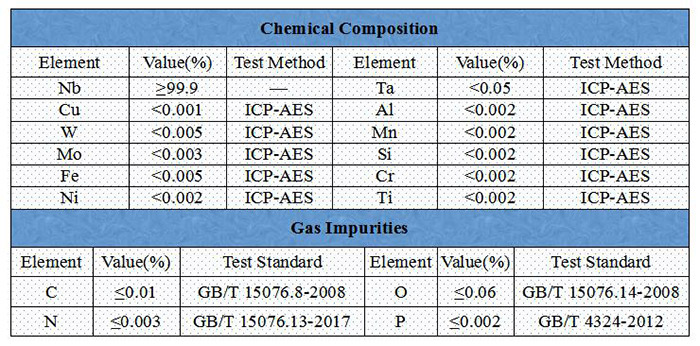

Composition (percentage by mass) of Spherical Niobium Powder:

Storage Condition of Spherical Niobium Powder:

Damp reunion will affect Spherical Niobium Powder powder dispersion performance and using effects, therefore,Spherical Niobium Powder Powder should be sealed in vacuum packing and stored in cool and dry room, the Spherical Niobium Powder Powder can not be exposure to air. In addition, the Spherical Niobium Powder powder should be avoided under stress.

Packing & Shipping of Spherical Niobium Powder:

We have many different kinds of packing which depends on the Spherical Niobium Powder Powder quantity.

Spherical Niobium Powder Powder packing:vacuum packing, 100g, 500g or 1kg/bag, 25kg/barrel, or as your request.

Spherical Niobium Powder Powder shipping:could be shipped out by sea , by air, by express as soon as possible once payment receipt.

Luoyang Tongrun Nano Technology Co. Ltd. (TRUNNANO) is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality chemicals and Nanomaterials, including boron powder, nitride powder, graphite powder, zinc sulfide, 3D printing powder, etc.

If you are looking for 3D printing metal powder, please feel free to contact us and send an inquiry, email address: sales2@nanotrun.com

3D Printing Alloy Spherical Niobium Powder Properties |

|

| Other Names | Niobium Powder |

| CAS No. | N/A |

| Compound Formula | Nb |

| Molecular Weight | N/A |

| Appearance | Gray metallic solid in various forms (ingot, tubing, pieces, powder) |

| Melting Point | N/A |

| Solubility in water | N/A |

| Density | NA |

| Purity | N/A |

| Particle Size | 0-20μm, 15-45μm, 15-53μm, 53-105μm, 53-150μm, 105-250μm |

| Boling point | N/A |

| Specific Heat | N/A |

| Thermal Conductivity | N/A |

| Thermal Expansion | N/A |

| Young's Modulus | N/A |

| Exact Mass | N/A |

| Monoisotopic Mass | N/A |

3D Printing Alloy Spherical Niobium Powder Health & Safety Information |

|

| Safety Warning | N/A |

| Hazard Statements | N/A |

| Flashing point | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| RTECS Number | N/A |

| Transport Information | N/A |

| WGK Germany | N/A |

Welcome to contact with us, email address: sales2@nanotrun.com

3D printing technology emerged in the mid-1990s and is actually the latest rapid prototyping device utilizing technologies such as light curing and paper lamination. It is basically the same as ordinary printing. The printer is equipped with "printing materials" such as liquid or powder. After connecting to the computer, the "printing materials" are superimposed layer by layer through computer control, and finally the blueprint on the computer is turned into a real thing. This printing technology is called 3D stereo printing technology.Our company is a strong company that provides excellent 3D printing Spherical Niobium Powder. If you need 3D printing and Spherical Niobium Powder, please feel free to contact us.

Inquiry us

PREVIOUS Products

High Purity Molybdenum Disulfide MoS2 Powder CAS 1317-33-5, 99%

NEXT Products