Tungsten Disulfide as Solid Lubricating Material

Aluminium buyers in the US physical metal market have held off on new orders amid fears of a recession triggered by rising inflation and supply chain crises.

Spot aluminium trading on the market has been suspended in recent weeks, according to industry sources, as uncertainty has increased following the outbreak of the conflict between Russia and Ukraine. Even before the war, the aluminium market was suffering from long waiting times and weak demand.

For aluminium buyers, recent poor US economic data have been a big factor in delaying purchases. Data released last month showed that the ISM manufacturing PMI came in at 57.1 in March, below expectations of 59 and down from 58.6 in February, unexpectedly hitting the lowest reading since September 2020. This was mainly due to a slowdown in new orders and WS2 powder are expected to increase in the future.

Tungsten disulfide, as a new type of solid lubricating material, its chemical properties are relatively stable. It can adapt to a variety of extremely harsh conditions, to provide maximum wear resistance, rust, and corrosion protection. And it is environmentally friendly, is not toxic, and will not cause harm to human health. It can be widely used in the automotive industry.

Tungsten disulfide has a layered crystal structure. It has excellent lubricity, with a very low friction coefficient, the dynamic friction coefficient is 0.030, and the static friction coefficient is 0.070. It is coated on the surface of automobile parts, can greatly reduce wear, and bite, eliminate or reduce the friction, and wear caused by equipment maintenance, maintenance, and other problems, and improve the working efficiency and service life of automobile parts.

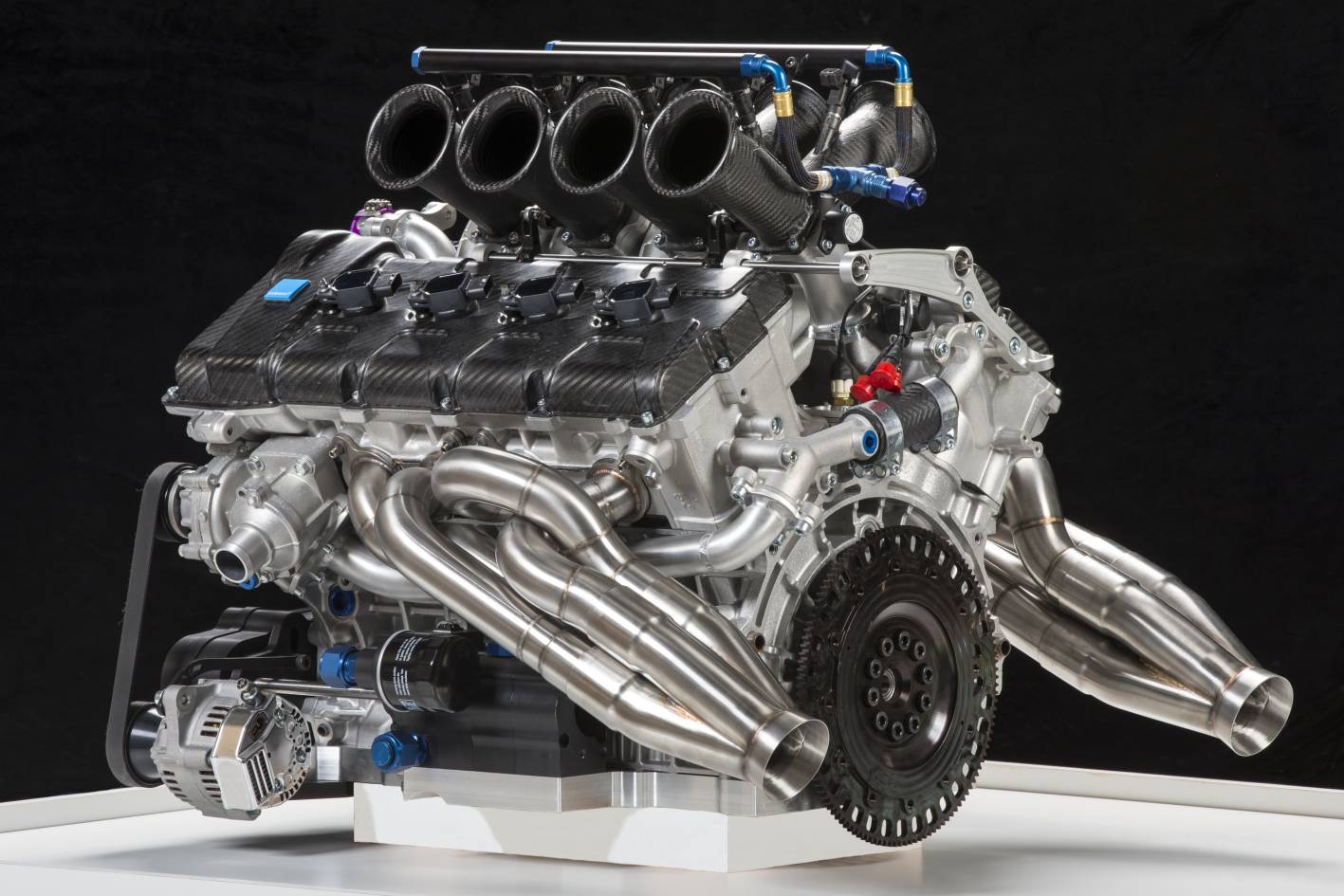

When the engine is running, the temperature is very high, and the pistons are turning back and forth at a very high speed. Operating in such harsh conditions, pistons wear out faster. Because the friction coefficient of tungsten disulfide is small, the parts used for high temperature or heavy load friction can also maintain a lubrication effect. At this point, it is coated on the surface of the piston, which will reduce wear, reduce temperature, and prolong the service life.

The piston ring is the least durable part of the engine. The piston ring rotates with the piston at high speed and is affected by the high temperature and high-pressure gas in the cylinder. The oil is particularly prone to deterioration at high temperatures, so its wear is very serious. With tungsten disulfide, friction is reduced and it is possible to move with the piston at high speed, high pressure, high temperature, and extremely difficult lubrication conditions.

The crankshaft is one of the most important parts of the engine, and its working state is also high-speed rotation, so it must be able to resist wear and fatigue. Journal surface is generally after high-frequency quenching or nitriding treatment, its surface coated with tungsten disulfide and fine grinding, and its wear resistance and fatigue strength will be greatly improved.

The universal joint, steering knuckle, spring steel bushing, front, and rear brake CAM bushing, are relatively difficult to be greased. In frequent operation, the lubricating oil will deteriorate and lose lubrication effect, and tungsten disulfide has excellent mechanical stability and thermal stability, which can well ensure that these parts enjoy lubrication effect and reduce wear.

Tungsten disulfide has excellent compatibility, water erosion resistance, and affinity with most paints, solvents, and fuels. It ensures that there is always a layer of lubrication on the surface of the bearings in the water pump and the silicone fan clutch as well as the helical gears that drive the distributor, so as to protect against rust and corrosion.

With these excellent properties, tungsten disulfide can also be used in the machinery industry, plastic industry, medical equipment industry, as well as military, aerospace, satellite, spacecraft, and other high-tech fields.

Luoyang Tongrun Nano Technology Co. Ltd. (TRUNNANO) is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality chemicals and Nanomaterials, including silicon powder, nitride powder, graphite powder, zinc sulfide, calcium nitride, 3D printing powder, etc.

If you are looking for high-quality tungsten disulfide WS2 powder, please feel free to contact us and send an inquiry. ([email protected])

Our company is a strong company that provides excellent 3D printing WS2 powder. If you need 3D printing and WS2 powder, please feel free to contact us.

Inquiry us

NEXT NEWS